According to the IMO`s climate protection plan, CO2 emissions from all ships should be eliminated by 2050.

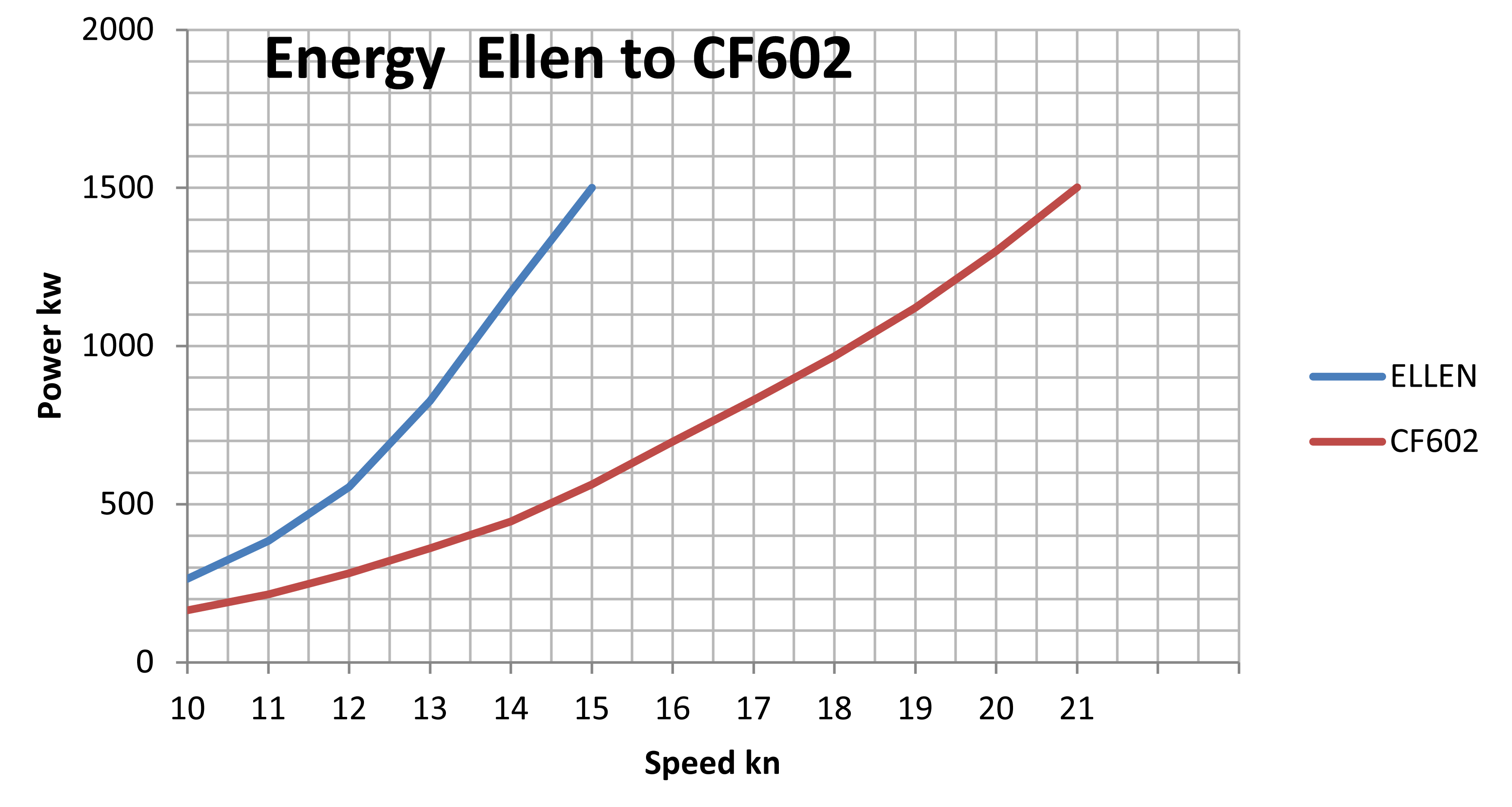

The most important primary energy source will than be electricity. Almost fuels aviable at time, from hydrogen to eFuels, will be based on electrical energy. However, such fuels are extensive, and teh efficiency of ships will become considerably more important in the future. Thanks to new composite materials, we can now build much lighter ships and thus save around half of the total energy consuption, depending on the load.